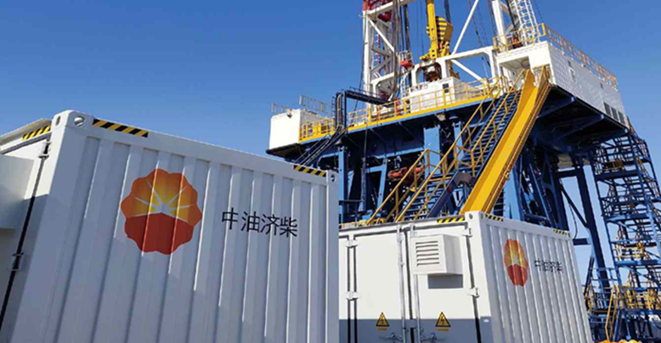

Mobile Energy Storage System for Drilling

The mobile energy storage system for drilling mainly consists of liquid-cooled battery compartment, energy storage inverter, transformer, and EMS energy management system.

Product Introduction

The working conditions of energy storage system at the drilling site include high-speed lifting of traveling block, low-speed tripping, lifting of mud pump, high-speed lifting of drilling tool, lowering of drilling tool, logging for drill-down, logging, casing running, well cementation, drilling, picking up stands and so on. The performance matching test of energy storage inverter is carried out under the condition of high-speed lifting of traveling block with the greatest power impact, which can adapt to the impact of heavy load of the winch and provide power supply guarantee for complex drilling process. The mobile energy storage system for drilling mainly consists of liquid-cooled battery compartment, energy storage inverter, transformer, and EMS energy management system.

Technical Parameter

Name | Technical parameters | Name | Technical parameters |

Capacity of mobile energy storage compartment | 3.34MWh | Charging and discharging power of energy storage inverter skid | 3.45MW |

Charging and discharging power of energy storage compartment | 1.67MW | ||

Protection level | IP54 | Protection level | IP54 |

Cooling method | Liquid cooling | Cooling method | Air cooling |

Fire protection scheme | Perfluorohexanone | Operating ambient temperature | -35°C〜+55°C |

Dimension (length * width * height) | 5200mm*2600mm*2900mm | Dimension (length * width * height) | 6200mm*3000mm*3000mm |

Weight | 33T | Weight | 20T |

Applicable scenarios

It can be widely used in drilling with electric drilling rig, workover, electric drive fracturing, pressure drive and other operation scenarios, as well as the energy storage projects that need to be matched on the grid side.