marine motor for sale-manufacture,factory,supplier from China

Product Introduction

The working conditions of energy storage system at the drilling site include high-speed lifting of traveling block, low-speed tripping, lifting of mud pump, high-speed lifting of drilling tool, lowering of drilling tool, logging for drill-down, logging, casing running, well cementation, drilling, picking up stands and so on. The performance matching test of energy storage inverter is carried out under the condition of high-speed lifting of traveling block with the greatest power impact, which can adapt to the impact of heavy load of the winch and provide power supply guarantee for complex drilling process. The mobile energy storage system for drilling mainly consists of liquid-cooled battery compartment, energy storage inverter, transformer, and EMS energy management system.

Technical Parameter

Name | Technical parameters | Name | Technical parameters |

Capacity of mobile energy storage compartment | 3.34MWh | Charging and discharging power of energy storage inverter skid | 3.45MW |

Charging and discharging power of energy storage compartment | 1.67MW | ||

Protection level | IP54 | Protection level | IP54 |

Cooling method | Liquid cooling | Cooling method | Air cooling |

Fire protection scheme | Perfluorohexanone | Operating ambient temperature | -35°C〜+55°C |

Dimension (length * width * height) | 5200mm*2600mm*2900mm | Dimension (length * width * height) | 6200mm*3000mm*3000mm |

Weight | 33T | Weight | 20T |

Applicable scenarios

It can be widely used in drilling with electric drilling rig, workover, electric drive fracturing, pressure drive and other operation scenarios, as well as the energy storage projects that need to be matched on the grid side.

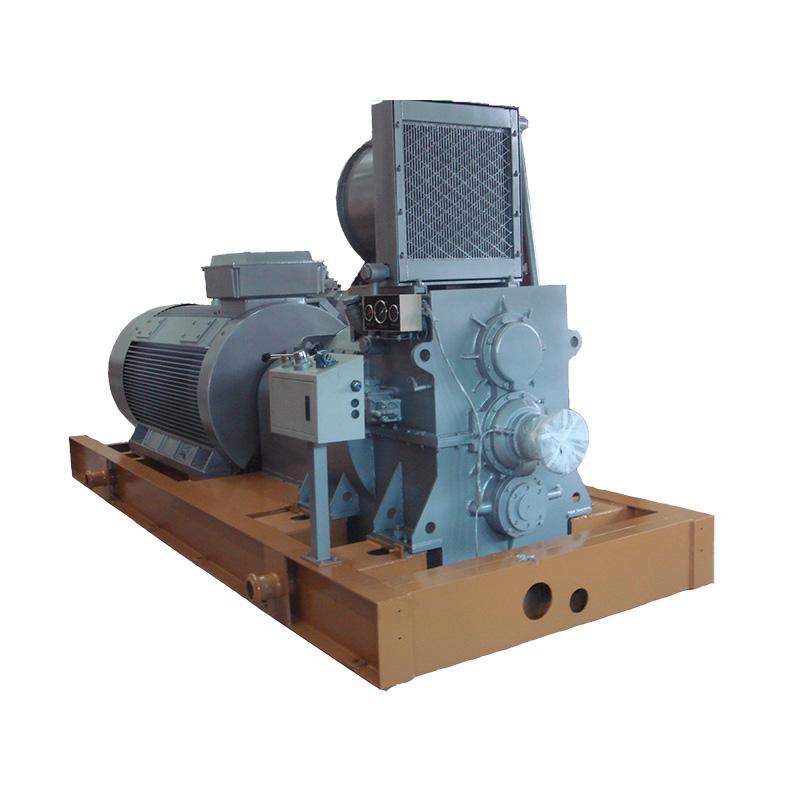

The electric motor coupling power unit is driven by electric motors and makes full use of power grid resources, which realizes the electric driving transformation of traditional mechanical drilling machine, reduces drilling cost, improves economic benefits, effectively reduces drilling noise, and has no exhaust emission, thus greatly improving the working environment. The unit is powered by a high-power electric motor, and users can make full use of cheap grid power resources to reduce the drilling cost by 30% ~ 45%. It is especially suitable for areas with long drilling cycles, complicated geological conditions, inconvenient transportation and concentrated well locations.

| Technical parameter | Input RPM | 600~1500 r/min | |

| Power ange | 300~1200 kW | ||

| Rated slip | 3% | ||

| Rated efficiency | ≥96% | ||

| Reduction ratio | 1.1~3.3 | ||

| Speed range | 1/3 | ||

Product Introduction

Having the advantages of intrinsic safety and independent design of system power and capacity, the all-vanadium liquid flow energy storage system can be applied to scenarios of special demand, such as remote well sites, and can meet the long-term energy storage demand for more than 4 h. Therefore, it has significant technical advantages in the construction of zero-carbon well sites in oil fields. The whole product is of container type, facilitating management, and operation and maintenance. The system features low self-discharge performance and low capacity attenuation rate, and the comprehensive efficiency can reach over 70%.

Technical Parameters

Parameters of energy storage system | 125kW/500kWh | 500kW power module | 1MW/4MWh |

Rated power | 125kW | 500kW | 1MW |

Voltage range | 3240~372V | 312V~498 | 623V~996 |

Single stack power | 32kW | 42kW | 42kW |

DC system efficiency | ≥80% | ≥80% | ≥80% |

Operating ambient temperature | -20℃~40℃ | -20℃~55℃ | -20℃~55℃ |

Nominal capacity | 500kWh | 1 - 5MWh (flexible design) | 4MWh |

Maximum current | 512A | 1603A | 1603A |

Number of stacks | 4 | 12 | 24 |

Comprehensive system efficiency | ≥70% | ≥70% | ≥70% |

Operating ambient humidity | 5%~95%RH | 5%~95%RH | 5%~95%RH |

Applicable Scenarios

Power grid: the system can be used for peak shaving, frequency modulation, new energy grid-connected and standby power supply; industrial and commercial energy storage: it is used for “peak shaving and valley filling” of the power consumption to achieve peak-valley arbitrage; microgrid power supply of remote or isolated island; distributed energy storage system: it integrates wind and solar energy storage, and is used for the construction of zero-carbon well sites, communities or standby power supplies.

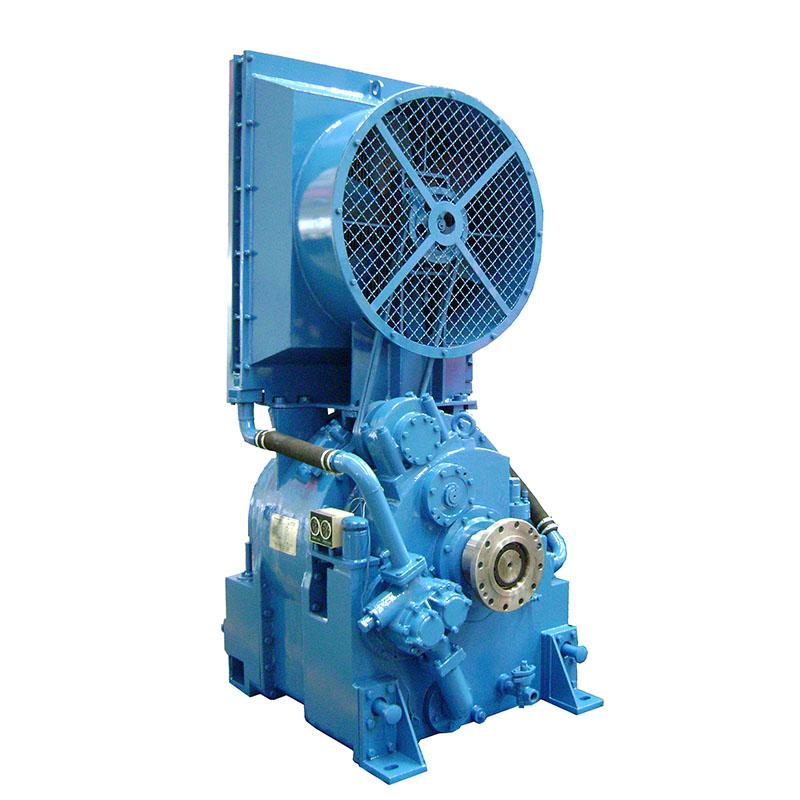

The hydraulic torque converter is a flexible transmission device installed between the power machine (such as diesel engine and electric motor) and the working machine (such as a winch, rotary table, and drilling pump), using mineral oil as the working medium and transmitting power of the power machine to the working machine.YBLT900 hydraulic torque converter is a centrifugal turbine torque converter with a charging and adjusting valve and its working chamber diameter is 900mm.It is compatible with G12V190PZL (or CAT3512) diesel engines and is mainly used on oil rigs.

| Technical specification | Maximum input speed | 1500 r/min |

| Maximum input power | 810kW | |

| Maximum input moment | 6.5k Nm | |

| Maximum output moment | 38.0 km | |

| Peak efficiency | 85±2% | |

| Cavity diameter | 900 mm | |

| Fuel supply pressure | 0.3~0.47 MPa | |

| Operating oil temperature | ≤110℃ | |

| Net quality | 2100kg | |

| Overall dimension (length × width × height) | 1330×950×1073 mm |

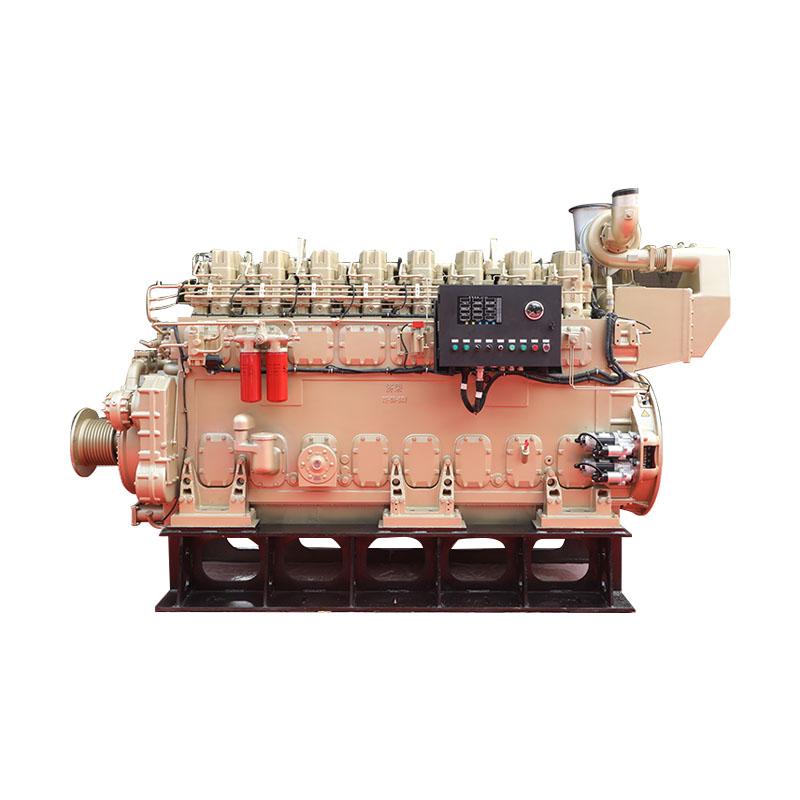

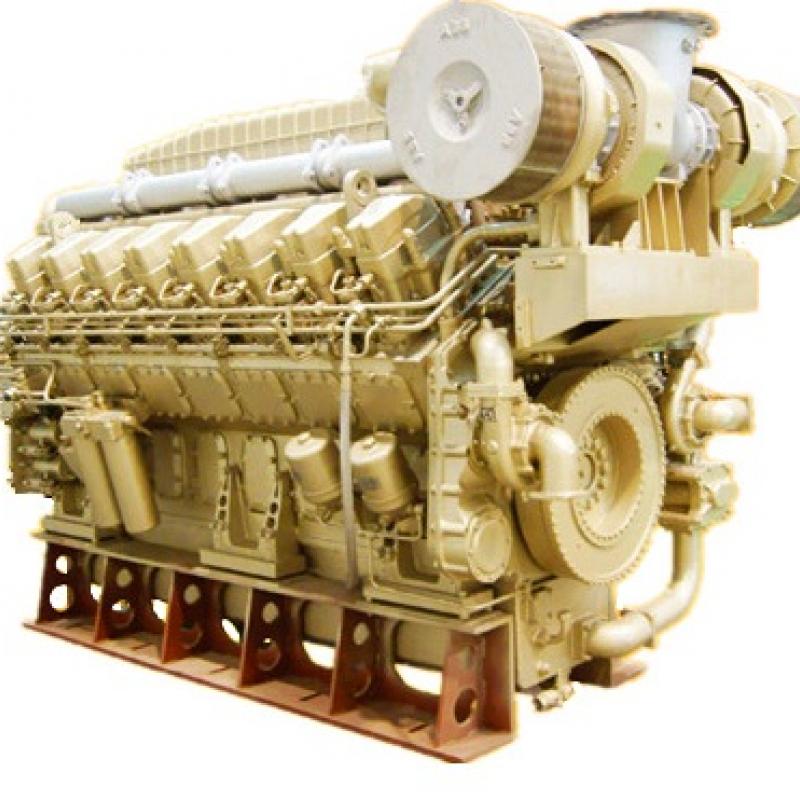

Series 3000 marine engine is a kind of diesel engine with the character high supercharging, high power, low fuel consumption, high reliability, and long service life. In its design, it absorbs and draws lessons from the advanced structural technology of foreign diesel engines. The crankshaft, engine block, cylinder head, connecting rod, camshaft, and other main important parts are basically universal with 601 series diesel engines.t can also be regarded as an improved model in the application filed on the basis of 601 series diesel engine, whose dynamic performance and economic indexes have been greatly improved. The crankshaft structure with double-end output is adopted, and the connection mode of output end is designed according to the SAE standard. It can be equipped with gearbox sets and pump sets, which is suitable for the transport ship and engineering ship. All products have passed CCS certification.

| Model | Type | Cylinders & Arrangement | Cylinders bore,mm | Piston stroke,mm | Rated power,kw/hp | RPM,r/min | Total piston displacement,L | Fuel oil consumption rate,g/kW.h | Lub. oil consumption rate,kW.h | Dimension mm | Weight kg |

| A12V190ZLC | Four-stroke, pressurized intercooler, water-cooled, direct-injection combustor | 12 cylinders V type | 190 | 215 | 1200/1630 | 1500 | 73.15 | ≤205 | ≤1.0 | 2969×1907×2206 | 9300 |

| A12V190ZLC1 | 1080/1470 | 1350 | |||||||||

| A12V190ZLC-1 | 900/1225 | 1200 | |||||||||

| A12V190ZLC-2 | 810/1100 | 1000 |

Product introduction

280Ah/314Ah/587Ah cells are adopted for the products of centralized lithium iron phosphate battery energy storage system. The single cabinet capacity of air-cooled battery compartment is 1.5 - 3.35 MWh, and the single cabin of liquid cooling system can reach 2 - 6 MWh. It is equipped with all-in-one machine of converter and booster, which meets the requirements of 0.25C - 1C charge and discharge rate, and features high safety, long service life and low cost. The product is suitable for the supporting energy storage systems of new energy power stations, and can be applied to large-scale energy storage systems on the power generation side and the power grid side. The energy storage battery system integrates battery module, high-precision BMS management system, lighting, intelligent temperature control and fire protection module, and adopts skid-mounted structure design. The protection level of the whole machine can reach IP55, and it supports the voltage level of 1500V/1000V, which meets the multi-scene applications such as peak regulation on new energy generation side and power grid side. It is suitable for PCS equipment with power level of 1250kW/1725kW/2500kW, compatible with the configuration schemes of 2-h, 3-h and 4-h energy storage system, capable of performing core functions such as peak shaving and valley filling, smooth power output and dynamic capacity increase, supports coordinated operation with photovoltaic and wind power systems, and provide diversified energy management services such as emergency power backup, frequency modulation and peak regulation.

Function Features

Prefabricated battery compartment | Battery compartment capacity (MWh) | 3.35 | 3.35 | 5.015 | 6.251 |

Cell capacity (Ah) | 280 | 280 | 314 | 587 | |

Nominal voltage (V) | 3.2 | 3.2 | 3.2 | 3.2 | |

Plug-in box combination mode | 1P16S | 1P52S | 1P52S/1P104S | 1P104S | |

Standard charging and discharging current (A) | 140 | 140 | 157 | 293.5 | |

Cluster combination mode | 1P416S | 1P416S | IP416S | IP416S | |

Cluster nominal energy (kWh) | 372.736 | 372.736 | 417.997 | 781.414 | |

Voltage range (V) | 1040〜1518.4 | 1040〜1518.4 | 1040〜1518.4 | 1040〜1518.4 | |

Stack combination mode | 9P416S | 9P416S | 12P416S | 8P416S | |

Cooling method | Air cooling | Liquid cooling | Liquid cooling | Liquid cooling | |

Firefighting system | Perfluorohexanone, compartment class | Perfluorohexanone, Pack grade | Perfluorohexanone, Pack grade | Perfluorohexanone, Pack grade | |

Container specification | 32 ft | 20 ft | 20 ft | 20 ft | |

Weight (t) | 40 | 36 | 45 | 49 | |

All-in-one machine of converter and booster | Rated power (MW) | 3.45 | 3.45 | 5 | 6.9 |

Transformer capacity (MVA) | 3.45 | 3.45 | 5 | 6.9 |

Applicable Scenarios

Large-scale centralized photovoltaic and wind power, distributed photovoltaic and wind power, power auxiliary service, peak-valley arbitrage, power capacity increase.

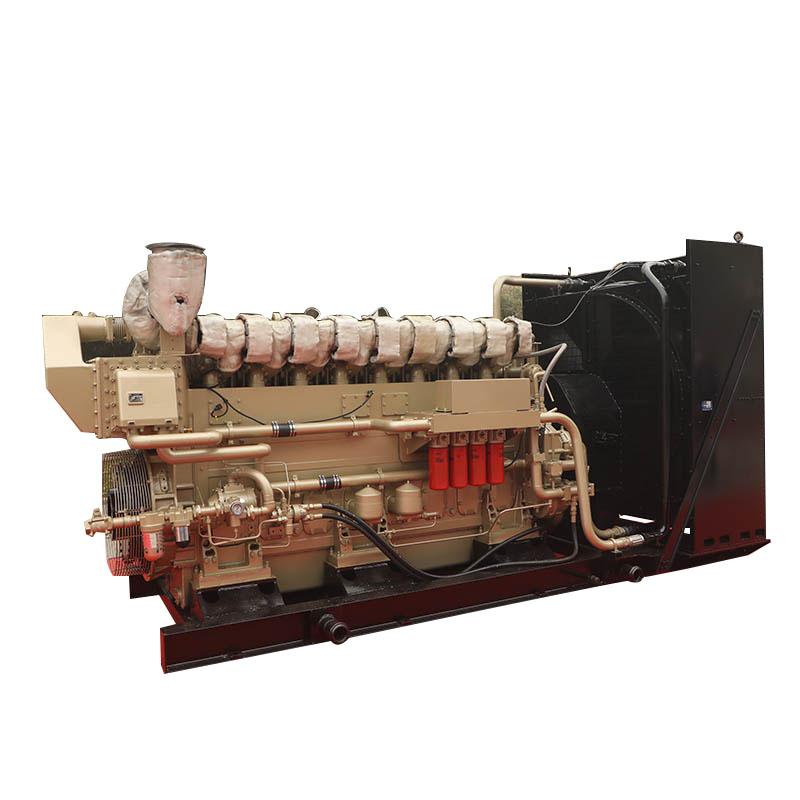

Series 4000 long-stroke diesel engines are V-type 12 cylinders diesel engines, which are designed according to the domestic and foreign internal combustion engine industry dynamics, aiming at designing for the mechanical equipment and power unit with large load variation. This engine adopts the advanced computer-aided software, simulates and analyses the key system of the whole machine and various calculation, through comparison of several design schemes selection to ensure the rationality of the design, and combined with its own product research and development experience, fully considered in the design of the oil drilling, Marine, gas machine application, and other areas of the market, in such aspects as performance, reliability, fuel economy and has a strong advantage in comparison to similar products at home and abroad. All products have passed CCS certification.

| Model | Type | Cylinders & Arrangement | Cylinders bore,mm | Piston stroke,mm | Rated power,kw/hp | RPM,r/min | Total piston displacement,L | Fuel oil consumption rate,g/kW.h | Lub. oil consumption rate,kW.h | Dimension mm | Weight kg |

| L8190ZLC | Four stroke, pressurized intercooled, water-cooled, direct-injection combustor | 8 cylinders, in-line | 190 | 255 | 830/1129 | 1000 | 57.84 | ≤200 | ≤1.0 | 3144×1571×2246 | 8500 |

| L8190ZLC-1 | 1000/1361 | 1200 | |||||||||

| L8190ZLC-2 | 550/748 | 900 | |||||||||

| L6190ZLC | 6 cylinders, in-line | 540/735 | 900 | 43.38 | ≤200 | 3144×1571×2246 | 7200 | ||||

| L6190ZLC-1 | 750/1020 | 1200 | |||||||||

| L6190ZLC-2 | 625/850 | 1000 | |||||||||

| L12V190ZLC-1 | 12 cylinders V type | 1200/1633 | 1200 | 86.72 | ≤188 | ≤0.9 | 2950×1980×2312 | 9300 | |||

| L12V190ZLC-2 | 1000/1361 | 1000 |

Series 4000 long-stroke diesel engine is designed and developed according to the current domestic and foreign internal combustion engine industry development situation, combining with Austria AVL simulation analysis software from Liszt, and combining with its own years of product research and development experience and cooperation with domestic universities and research institutions.

The dynamic performance, economic performance, reliable performance, and other indicators of the product have reached the international level, with the characteristics of compact shape, simple operation, and maintenance, high power index, it can match 50Hz and 60Hz frequency operated motor and meet various power needs.

| Description | Engine model | Injection system | Speed adjustment mode | Cylinder&Arrangement | Cylinders bore,mm | Piston stroke,mm |

| Engine with fan and radiator | BL12V190PZL-1 | Monoblock Pump | Hydraulic or Electro-hydraulic Governor | 12 cylinders,V type | 190 | 255 |

| BL12V190PZL-2 | ||||||

| BL12V190PZL-3 | ||||||

| AL8190PZLG-1 | ECU Electric Control Monoblock Pump | Electronic speed governor | 8 cylinders L type | |||

| AL8190PZLG-3 | ||||||

| Description | Genset model | Rated power kw | Ratation speed r/min | Engine model | Hydraulic transmission coupler/Torque Converter Model | Height of center |

| Hydraulic transmission coupling set | BL12V190PZL-3/O | 1300 | 1300 | BL12V190PZL-3 | YOZJ875 | 760 |

| CO1300-3/20 |

Product Introduction

Hybrid microgrid system is a system composed of generator set driven by internal combustion engine, battery pack, supercapacitor, and control system. It is mainly used to provide the required power source through the generator set driven by internal combustion engine, store the electric energy generated by the power source through the battery pack and output the electric energy required for operation alone or together with the power source, and stabilize the microgrid voltage through quickly charging and discharging of the energy storage system to cope with the impact load of the island power station, so as to reduce the configuration capacity of the power unit and improve the energy utilization.

Technical Parameter

Name | Technical parameters |

Rated capacity of supercapacitor | 600kW |

Capacity of lithium iron phosphate battery | 600kW/691kWh |

Rated voltage | 0.6kV |

Compensation time | 0〜15s |

Load-side voltage imbalance | ≤4% |

Response time of whole machine | ≤20ms |

Total voltage distortion rate | ≤4% |

Applicable Scenarios

Large load range and frequency modulation of operating condition of frequent frequency variation during power generation, transmission, distribution and utilization.

4000 series long-stroke diesel engines are designed and developed according to the current development of the internal combustion engine industry at domestic and abroad, combining with AVL simulation and analysis software of Liszt in Cooperation with domestic universities and research institutions with years of product development experience. The dynamic performance, economic performance, reliable performance, and other indicators of the product have reached the international level, with a compact shape, simple operation, and maintenance, high power index characteristics, which can match 50Hz and 60Hz frequency-operated motor and meet various power needs.

| Engine model | Fuel injection system | Cylinders & Arrangement | Cylinder bore,mm | Piston stroke,mm | Power kW | RPM,r/min | Total piston displacement,L | Fuel Consumption Rate,g/kW.h | Lub. oil comsumption,g/kW.h |

| BL12V190ZL-1 | Four-stroke, pressurized intercooler, water-cooled, direct-injection combustor | 12 cylinders V type | 190 | 255 | 1320 | 1260 | 86.72 | ≤200 | ≤1.0 |

| BL12V190ZL-2 | 12 cylinders V type | 1100 | 1000 | 86.72 | ≤200 | ≤1.0 | |||

| BL12V190ZL-3 | 12 cylinders V type | 1440 | 1360 | 86.72 | ≤200 | ≤1.0 | |||

| Genset Model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage V | Frequency Hz | Power Factor | Genset Dimension mm | Weight kg |

| 1100GF8 | BL12V190ZL1-2 | IFC series | 1100 | 1000 | 600 | 50 | 0.7 | 6250×2252×2739 | 19000 |

| 1000GF6 | BL12V190ZL-2 | 1000 | 1000 | ||||||

| 1000GF7 | BL12V190ZLD-2 | 1000 | 1000 |

Series 6000 diesel engines is developed by Jichai incorporate with Austria AVL company and domestic well-known colleges and universities, research institutes cooperation, by means of the latest development of internal combustion engine, through the computer-aided design, simulation, finite element analysis research of engine combustion process, such as crankshaft torsional vibration, turbocharger matching, into the exhaust system on the basis of the simulation, optimization of design and development6000 series land diesel engine is a cooperation between Jichai and AVL of Austria as well as famous universities and research institutes in China,use the latest development methods for the internal combustion engine, designed and developed through computer-aided design, simulation calculation, finite element analysis and research on the engine combustion process, crankshaft torsional vibration, supercharger matching, intake, and exhaust system. The advanced technology and mature spare parts of the international high-power internal combustion engine industry are adopted, so that the engine has made great progress in increasing the average effective pressure, reducing fuel consumption and emission, and improving the reliability and safety while expanding the power of the original 190 series diesel engine. Widely used in oil drilling, Marine power, offshore drilling platform, power generation, and other fields.

| Engine model | Fuel injection system | Cylinders & Arrangement | Cylinder bore,mm | Piston stroke,mm | Power KW | RPM,r/min | Total piston displacement,L | Fuel Consumption Rate,g/kW.h | Lub. oil comsumption,g/kW.h |

| H12V190ZL | Four stroke, pressurized intercooled, water-cooled, direct-injection combustor | 12 cylinders V type | 190 | 215 | 1566 | 1500 | 73.15 | ≤200 | ≤1.0 |

| H12V190ZL-1 | 12 cylinders V type | 1270 | 1200 | 73.15 | ≤200 | ≤1.0 | |||

| H12V190ZL-2 | 12 cylinders V type | 1050 | 1000 | 73.15 | ≤200 | ≤1.0 | |||

| H16V190ZL | 16 cylinders V type | 2180 | 1500 | 97.53 | ≤200 | ≤1.0 | |||

| H16V190ZL-1 | 16 cylinders V type | 1745 | 1200 | 97.53 | ≤200 | ≤1.0 | |||

| H16V190ZL-2 | 16 cylinders V type | 1455 | 1000 | 97.53 | ≤200 | ≤1.0 | |||

| H16V190ZL-3 | 16 cylinders V type | 1870 | 1300 | 97.53 | ≤200 | ≤1.0 | |||

| Genset Model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage V | Frequency Hz | Power Factor | Genset Dimension mm | Weight kg |

| 1500GF | H12V190ZL | 1500 | 1500 | 400/6300/10500 | 50 | 0.8 | 7880×2869×3175 | 19100 | |

| 2000GFZ6 | H16V190ZL | JFG series | 1500 | 1500 | 10500 | 19500 | |||

| 2000GFZ9 | H16V190ZL | 1500 | 1500 | 5930×2180×2421 | 17000 | ||||

| 1500GF2 | H16V190ZL-1 | IFC series | 1500 | 1200 | 480/13800 | 60 | 7880×2869×3175 | 19500 | |

| 1400GF | H16V190ZL-2 | 2000 | 1000 | 400/6300/10500 | 50 | 9060×2869×3175 | 24000 |

Series 26/32 natural gas engines are high-power natural gas engines with independent intellectual property rights launched by Jichai to meet the demand of national energy conservation and emission reduction projects, such as long-distance pipeline compressor driving power, offshore drilling platform power, large gas-fired power station, and distributed energy. It has high pressure, high power, high efficiency, low discharge, green, environmental protection, and other characteristics. The engine's gas consumption rate is 8500kJ/kW·h, and its thermal efficiency is higher than 44%. Its power performance, economy and reliability have reached the international advanced level.

| Engine model | Cylinders & Arrangement | Cylinder bore,mm | Piston stroke,mm | Rated power ,kW | RPM,r/min | Total piston displacement,L | Heat consumption ratekJ/kW.h | Lub. oil consumption rate g/kW.h | Start method |

| 16V26/32T | 16cylinders ,V type | 260 | 320 | 4200 | 1000 | 272 | ≤8181 | ≤0.6 | Gas |

| 3780 | 900 | ||||||||

| 12V26/32T | 12 cylinders, V type | 260 | 320 | 3150 | 1000 | 204 | |||

| 2835 | 900 | ||||||||

| Genset Model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage KV | Frequency Hz | Power factor | Dimension mm | Weight kg |

| 4000GF-T | 16V26/32T | The standard configuration is Leleisemar motor | 4000 | 1000 | 6.3/10.5 | 50 | 0.8 | 9435x2930x4175 | 70000 |

| 3600GF-T | 16V26/32T | 3600 | 900 | 13.8 | 60 | ||||

| 3000GF-T | 12V26/32T | 3000 | 1000 | 6.3/10.5 | 50 | 8330x2930x3638 | 48000 | ||

| 2700GF-T | 12V26/32T | 2700 | 900 | 13.8 | 60 |

Series 26/32engines include V-12, 16, 18 cylinders, and in-line 6, 8, and 9 cylinder serials. The design is based on 12V/2632 diesel engines, whose fuel involves diesel, heavy oil, and natural gas. It is a highly pressurized engine with full intellectual property rights developed by Jichai and AVL Of Austria. It is a series of medium-speed engines with high pressurization, great success, low fuel consumption, high reliability, and long life, which is developed by Jichai and AVL of Austria which Jichai has 100% intellectual property rights. It uses the world's leading high-pressure common rail fuel system, greatly reducing camshaft size, dual electronic control system, high supercharging technology, ultra supercharging technology, MPC exhaust system. Strong Miler cycle, double stage intermediate cooling technology. Self-cleaning filtration technology greatly improves engine performance and emissions.

Series 26/32 heavy oil machine is a new product developed by Jichai to meet the needs of China's economic and environmental development. The key technical indexes of 26/32 series heavy oil engines, such as average pressure/fuel consumption rate, power, and emission, have reached or exceeded the international advanced level. As it burns heavy oil, it greatly reduces the running cost of the engine and has the characteristics of high reliability, low emission and high intelligence. It is well received by users of power equipment such as inland river shipping, dredging project, offshore oil equipment manufacturing, Chinese port construction, and large-scale power station.

| Model | Type | Cylinders & Arrangement | Cylinders bore,mm | Piston stroke,mm | Rated power,kw/hp | RPM,r/min | Total piston displacement,L | Fuel oil consumption rate,g/kW.h | Lub. oil consumption rate,kW.h | Dimension mm | Weight kg |

| 6L2632 | Four-stroke, supercharged intercooler, water cooling, high-pressure common rail ECU electronic control jet | 6 cylinders, in-line | 260 | 320 | 2085/2837 | 1000 | 102 | ≤184 | ≤0.6 | 5050×2160×3450 | 19700 |

| 8L2632 | 8 cylinders, in-line | 2780/3782 | 136 | 5950×2160×3450 | 26000 | ||||||

| 9L2632 | 9 cylinders, in-line | 3130/4259 | 153 | 6400×2160×3450 | 29500 | ||||||

| 12V2632 | 12 cylinders V type | 4170/5673 | 204 | 5830×2240×3355 | 39400 |

Series 6000 diesel engines are developed by Jichai with Austria AVL company and domestic well-known colleges and universities, research institutes, and by means of the latest development of internal combustion engine, with today's international big power internal combustion engine industry advanced technology and mature component products, make great progress in improving average effective pressure, reducing fuel consumption and improving reliability and safety while expanding the power of the original 190 series diesel engine. Widely used in oil drilling, Marine power, offshore drilling platform, power generation and other fields.

| Genset model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage V | Frequency Hz | Power factor | Dimension mm | Weight kg |

| 1500GF | H12V190ZL | JFG series | 1500 | 1500 | 400 | 50 | 0.8 | 7880×2869×3175 | 19100 |

| 2000GFZ6 | H16V190ZL | 1500 | 1500 | 10500 | 19500 | ||||

| 2000GFZ9 | H16V190ZL | 1500 | 1500 | 5930×2180×2421 | 17000 | ||||

| 1500GF2 | H16V190ZL-1 | IFC series | 1500 | 1200 | 480/13800 | 60 | 7880×2869×3175 | 19500 | |

| 1400GF | H16V190ZL-2 | 2000 | 1000 | 400/6300/10500 | 50 | 9060×2869×3175 | 24000 |

12V175 diesel engine has the characteristics of high supercharging, low energy consumption, high reliability, and long life,Its dynamic performance, economy, reliability, and emission index have reached the international advanced level through the use of electronic control, high-pressure common rail, Miller cycle, exhaust after-treatment, high-efficiency supercharger and other new technologies. The average effective pressure of diesel engine reaches 2.0mpa, the first overhaul period reaches 35,000 hours, and the bare engine emission meets GB20891 II. 12V175 diesel generator set is a high-performance power set developed for the working condition of an electric drilling machine. According to the characteristics of oilfield working conditions, the Genset been designed in such aspects as starting performance, sudden reduction capacity, and continuous working capacity: In order to realize unattended, the Genset installed a remote monitoring system, which realized the real-time recording of the Genset field data and remote monitoring on the Internet.

| Genset model | Engine model | Alternator model | Power kW | RPM,r/min | Voltage V | Frequency Hz | Power factor | Dimension mm | Weight kg |

| 1200GF50 | 12V175ZL-1 | IFC series | 1200 | 1500 | 600 | 50 | 0.7 | 8286×2800×2861 | 16600 |

| 1400GF | 12V175ZL | 1400 | 1800 | 60 |

Hydraulic Coupler widely used in the field of oil drilling and has become the standard configuration of the diesel coupling power units for oil drilling rigs.

| Technical parameter | Input speed | 600~1500 r/min | |

| Transfer power range | 600~1300 kW | ||

| Rated slip | 3% | ||

| Rated power | ≥96% | ||

| Reduction ratio | 1.1~3.3(According to user form a complete set of circumstances specific determination) | ||

| Characteristic | Independent air cooling | This type of hydraulic coupler adopts the same water-cooling system as the diesel engine, which is installed on the common chassis, easy to install and transport, safe and reliable to operate. | |

| Combined water cooling | This type of hydraulic coupler adopts an independent fan cooling system for the ahead gearbox, which is suitable for the selection of all types of drilling rigs. | ||

| Power range | 10~7500kW |

| Gas displacement | 0.1~500×104Nm3/d |

| Maximum exhaust pressure | 52MPaG |

| Application area | It can be used for gas collecting, gas production and gas injection (gas storage), oil and gas treatment and processing, gas lifting, light hydrocarbon recovery, natural gas liquefaction, refining, gas drilling, and pipeline pressure testing. |

| working medium | Natural gas, coal bed gas, shale gas, oil field associated gas, flash vapor, air, nitrogen, carbon dioxide, hydrogen, nitrogen hydrogen, and so on. |

Functional description:

1)The container is equipped with a distribution box to provide power to all low-voltage loads in the engine room, such as horizontal radiator fans, control screens, lighting, exhaust (supply) fans (for horizontal distribution), chargers, electric heating (optional), oil pumps, electric heating (optional), and outdoor searchlights. It can also be responsible for controlling related equipment (according to project configuration requirements);

2)Two track suspension beams and a hoist are installed on the top of the engine room, with a lifting capacity of 0.5 tons per beam;

3)Inlet of engine air filter and the engine room are equipped with electric heating devices to avoid freezing and blockage (optional);

4)The floor of the machine room is equipped with an axial drive mechanism for the generator, which enables the generator to detach from the coupling by 200mm. (Optional)

5)If the indoor heating temperature in the machine room is not lower than 5 ℃, an insulation layer needs to be installed under the chassis of the machine room, and electric heating heaters (optional) are used inside the machine room;

6)One explosion-proof acoustic and visual alarm lamp is installed outside each machine room. The lighting inside the machine room is an explosion-proof LED lamp with emergency function. Other equipment and boxes do not need to be explosion-proof (optional).

7)Ladder: Install a simple ladder at a suitable position on the box;

8)Configure the fire protection system in the machine room: Install dry powder fire extinguishers as fire extinguishing devices (standard), and other flame detectors, methane leak detectors, smoke detectors, etc. as optional options;

9)The machine room requires a silent type, with 85dB at 1m.

10)Note: The specific configuration shall be subject to the actual situation of the project.

Application case:

Functional description:

1)The container is equipped with a distribution box to provide power to all low-voltage loads in the engine room, such as horizontal radiator fans, control screens, lighting, exhaust (supply) fans (for horizontal distribution), chargers, electric heating (optional), oil pumps, electric heating (optional), and outdoor searchlights. It can also be responsible for controlling related equipment (according to project configuration requirements);

2)Two track suspension beams and a hoist are installed on the top of the engine room, with a lifting capacity of 0.5 tons per beam;

3)Inlet of engine air filter and the engine room are equipped with electric heating devices to avoid freezing and blockage (optional);

4)The floor of the machine room is equipped with an axial drive mechanism for the generator, which enables the generator to detach from the coupling by 200mm. (Optional)

5)If the indoor heating temperature in the machine room is not lower than 5 ℃, an insulation layer needs to be installed under the chassis of the machine room, and electric heating heaters (optional) are used inside the machine room;

6)One explosion-proof acoustic and visual alarm lamp is installed outside each machine room. The lighting inside the machine room is an explosion-proof LED lamp with emergency function. Other equipment and boxes do not need to be explosion-proof (optional).

7)Ladder: Install a simple ladder at a suitable position on the box;

8)Configure the fire protection system in the machine room: Install dry powder fire extinguishers as fire extinguishing devices (standard), and other flame detectors, methane leak detectors, smoke detectors, etc. as optional options;

9)Note: The specific configuration shall be subject to the actual situation of the project.

Application case:

Series 2000 is based on the Z12V190BC1 diesel engine awarded with the national Gold Award according to the service conditions and special requirements of Marine engines, the shafting, lubricating system, cooling system, intake, and exhaust system and monitoring system have been improved comprehensively from the aspects of safety, reliability and service mathe CCS certification.intenance. The gearbox can be used to reduce the speed and load of transport ships and engineering ships. It can meet the requirements of gas and electricity double starting, remote operation, engine parallel, and so on. The products cover a wide range of power, can meet the needs of customers in different power segments, products have passed.

| Model | Type | Cylinders & Arrangement | Cylinders bore,mm | Piston stroke,mm | Rated power,kw/hp | RPM,r/min | Total piston displacement,L | Fuel oil consumption rate,g/kW.h | Lub. oil consumption rate,kW.h | Dimension mm | Weight kg |

| 6190ZLC | Four stroke, pressurized intercooled, water-cooled, direct-injection combustor | 6 cylinders, in-line | 190 | 210 | 450/610 | 1450 | 35.73 | ≤204 | ≤1.2 | 2990×1243×1763 | 3960 |

| 6190ZLC-1 | 400/540 | 1200 | |||||||||

| 6190ZLC-2 | 330/450 | 1000 | |||||||||

| 6190ZLC-3 | 400/540 | 1300 | |||||||||

| B6190ZLC | 450/610 | 1450 | 3000×1324×1820 | ||||||||

| B6190ZLC-1 | 400/540 | 1200 | |||||||||

| B6190ZLC-2 | 330/450 | 1000 | |||||||||

| B6190ZLC-3 | 400/540 | 1300 | |||||||||

| 8190ZLC | 8 cylinders, in-line | 720/980 | 1450 | 47.63 | 3175×1220×2055 | 5200 | |||||

| 8190ZLC-1 | 600/816 | 1200 | |||||||||

| 8190ZLC-2 | 500/680 | 1000 | |||||||||

| 8190ZLC-3 | 650/884 | 1300 | |||||||||

| C6190ZLC | 6 cylinders, in-line | 230 | 550/748 | 1350 | 39.13 | ≤1.0 | 2995×1133×1754 | 3960 | |||

| C6190ZLC-1 | 490/667 | 1200 | |||||||||

| C6190ZLC-2 | 400/544 | 1000 | |||||||||

| C6190ZLC-3 | 530/721 | 1300 | |||||||||

| C8190ZLC | 8 cylinders, in-line | 540/735 | 1000 | 52.17 | 3180X1220X2055 | 5200 | |||||

| C8190ZLC-1 | 650/884 | 1200 | |||||||||

| C8190ZLC-2 | 700/952 | 1300 | |||||||||

| C8190ZLC-3 | 735/1000 | 1350 | |||||||||

| S6190ZLC-1 | 6 cylinders, in-line | 275 | 900/1225 | 1200 | 46.78 | ≤195 | ≤1.0 | 3144×1571×2246 | 7200 | ||

| S6190ZLC-2 | 750/1020 | 1000 | |||||||||

| S6190ZLC-4 | 675/918 | 900 | |||||||||

| S6190ZLC-5 | 825/1122 | 1100 | |||||||||

| S6190ZLC-7 | 535/728 | 750 | |||||||||

| AS6190ZLC-2 | 1000/1361 | 1200 | 3440×1405×2190 | 8200 | |||||||

| S8190ZLC-1 | 8 cylinders, in-line | 1200/1633 | 1200 | 62.38 | ≤195 | 3744X1571X2246 | 8500 | ||||

| S8190ZLC-2 | 1000/1361 | 1000 | |||||||||

| S8190ZLC-4 | 900/1245 | 900 | |||||||||

| S8190ZLC-5 | 1100/1497 | 1100 | |||||||||

| S8190ZLC-7 | 750/1020 | 750 | |||||||||

| AS8190ZLC-2 | Electronically controlled injection | 1320/1796 | 1200 | 4040X1410X2190 | |||||||

| G6190ZLC | Four stroke, pressurized intercooled, water-cooled, direct-injection combustor | 6 cylinders, in-line | 210 | 540/735 | 1450 | 35.37 | ≤204 | ≤1.2 | 2995×1259×1754 | 4500 | |

| G6190ZLC-1 | 450/612 | 1200 | |||||||||

| G6190ZLC-2 | 380/517 | 1000 | |||||||||

| G6190ZLC-3 | 480/653 | 1300 | |||||||||

| G12V190ZLC1 | 12 cylinders V type | 1000/1360 | 1450 | 71.45 | ≤209 | ≤1.6 | 3744.5×1571×2246 | 5800 | |||

| G12V190ZLC-1 | 750/1020 | 1200 | |||||||||

| G12V190ZLC-2 | 620/844 | 1000 | |||||||||

| G12V190ZLC-3 | 810/1102 | 1300 |

Compressor D seriescan be used for gas collecting, gas production and gas injection (gas storage), oil and gas treatment and processing, gas lifting, light hydrocarbon recovery, natural gas liquefaction, refining, gas drilling, and pipeline pressure testing.

| Power range | 10~7500kW |

| Gas displacement | 0.1~500×104Nm3/d |

| Maximum exhaust pressure | 52MPaG |

| Application area | It can be used for gas collecting, gas production and gas injection (gas storage), oil and gas treatment and processing, gas lifting, light hydrocarbon recovery, natural gas liquefaction, refining, gas drilling and pipeline pressure testing. |

| working medium | Natural gas, coal bed gas, shale gas, oil field associated gas, flash vapor, air, nitrogen, carbon dioxide, hydrogen, nitrogen hydrogen and so on. |

Series 6000 diesel engine is developed by Jichai with Austria AVL company and domestic well-known colleges and universities, research institutes, by using the latest development means of internal combustion engine and adopting the advanced technology and mature spare parts of the current international high-power internal combustion engine industry, The engine has made great progress in increasing average effective pressure, reducing fuel consumption and improving reliability and safety while expanding the power of the original 190 series diesel engine. Widely used in oil drilling, Marine power, offshore drilling platform, power generation, and other fields.

| Genset model | Rated power kw | Rotate speed r/min | Frequency Hz | Voltage V | Engine model | Power factor |

| 1200GF | 1200 | 1000 | 50 | 600 | H16V190ZL-2 | 0.7 |

| 1500GF | 1500 | 1200 | 60 | 600 | H16V190ZL-1 | 0.7 |

| 2000GF | 2000 | 1500 | 50 | 600 | H16V190ZL | 0.7 |

| Power range | 10~7500kW |

| Gas displacement | 0.1~500×104Nm3/d |

| Maximum exhaust pressure | 52MPaG |

| Application area | It can be used for gas collecting, gas production and gas injection (gas storage), oil and gas treatment and processing, gas lifting, light hydrocarbon recovery, natural gas liquefaction, refining, gas drilling and pipeline pressure testing. |

Series 6000 diesel engines are developed by Jichai with Austria AVL company and domestic well-known colleges and universities, research institutes cooperation, by means of the latest development of internal combustion engine, through the computer-aided design, simulation, finite element analysis research of engine combustion processes, such as crankshaft torsional vibration, turbocharger matching, inlet and exhaust system on the basis of the simulation, optimization of design and development. The advanced technology and mature spare parts of the international high-power internal combustion engine industry are adopted, so that the engine has made great progress in increasing the average effective pressure, reducing fuel consumption and emission, and improving the reliability and safety while expanding the power of the original 190 series diesel engine. Widely used in oil drilling, Marine power, offshore drilling platform, power generation, and other fields. All products have passed CCS certification.

| Model | Type | Cylinders & Arrangement | Cylinders bore,mm | Piston stroke,mm | Rated power,kw/hp | RPM,r/min | Total piston displacement,L | Fuel oil consumption rate,g/kW.h | Lub. oil consumption rate,kW.h | Dimension mm | Weight kg |

| H8L190ZLC | Four-stroke, pressurized intercooler, water-cooled, direct-injection combustor | 8 cylinders , in-line | 190 | 215 | 1000/1361 | 1450 | 48.77 | ≤200 | ≤1.0 | 3349×1416×2225 | 8200 |

| H8L190ZLC-1 | 830/1129 | 1200 | |||||||||

| H8L190ZLC-2 | 700/952 | 1000 | |||||||||

| H8L190ZLC-3 | 900/1245 | 1300 | |||||||||

| H12V190ZLC | 12 cylinders V type | 1680/2286 | 1450 | 73.15 | ≤196 | ≤0.8 | 3212×1597×2211 | 9500 | |||

| H12V190ZLC-2 | 1160/1578 | 1000 | |||||||||

| H12V190ZLC-1 | 1390/1891 | 1200 | |||||||||

| H12V190ZLC-3 | 1500/2041 | 1300 | |||||||||

| H16V190ZLC | 16 cylinders V type | 2200/2993 | 1500 | 97.53 | ≤196 | ≤0.8 | 3530×1880×2150 | 13000 | |||

| H16V190ZLC-1 | 1820/2476 | 1200 | |||||||||

| H16V190ZLC-2 | 1520/2068 | 1000 | |||||||||

| H16V190ZLC-3 | 1980/2694 | 1300 |